Clearkote has a unique ceramic structure that out performs any competitive coating and improves performance in both laboratory and real world settings.

Originally developed for firearms, exhaust systems pistons and high wear applications. It is literally a room temperature curing ceramic. When applied to anodized aluminum it permanently seals the surface against pitting, dulling, or streaking. Clearkote forms a chemical bond with the metal (as opposed to a mechanical bond like paint) so there is no chance of it peeling or chipping. It is extremely scratch resistant and resistant to most solvents and cleaners. It will keep your metal looking like new and indefinitely and completely eliminates the need for maintenance (beyond washing regularly) or re-polishing.

Glass does not break down. Ceramic items found thousands of years after they were made are still intact. This revolutionary product is the result of years of experimentation with inorganic coatings that began when NASA needed to develop a protectant for spacecraft components.

Clearkote is a room temperature-cured "ceramic" that renders metal surfaces unavailable for corrosion. Instead of attempting to keep moisture from getting to the metal, as organic coatings (paint and plastics) do, Clearkote actually creates a new surface that's part of the metal. Only abrasion and products with an extremely high alkaline content will affect it. If it does wear away or scratching in places, no spreading or failing will occur because there is no "scratch" layer of material on top of the metal as it is chemically bonded to the metal. In addition Clearkote is not affected by heat.

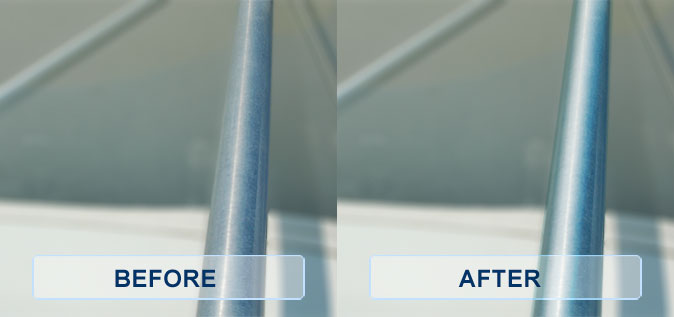

Surface PREPARATION is crucial. The metal, whether new or old, must be totally clean or the chemical bond will not properly take place. Clearkote can be used as a substitute for anodization and thus can even restore oxidized aluminum. When it is properly applied, the metal is left with a rich, clear satiny feel; leaving no streaks or flow lines.

Clearkote is applied after all finishing work, including welding is completely such that it protects all areas and attachments. The surface that is formed by the chemical reaction prevents oxygen from reaching the metal, thus eliminating further oxidation. The result is a new metal finish that is very highly resistant to the elements. The chemical reaction between Clearkote and the material to which it is applied results in the molecular formation of a glass-like layer which is virtually impenetrable by corrosion.